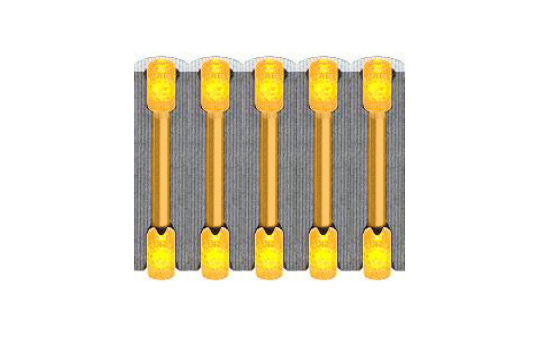

The connectors are constructed by two main components, insulating housing and an electrically conducting contact. The liquid crystal polymer insulators are molded and the contacts are a bundled gold-plated molybdenum wire. Gold plated copper spacers are used for long Z-axis connectors.

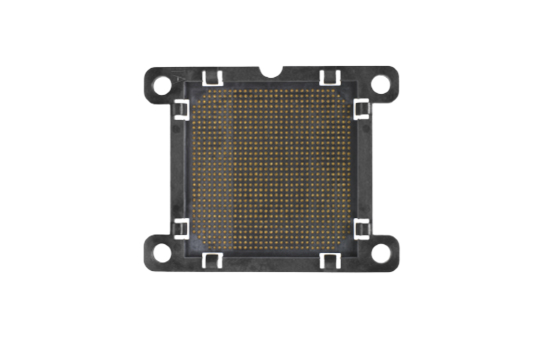

The positioning is designed into the insulating housing. Insulation housing are molded for high volume and machined for prototypes.

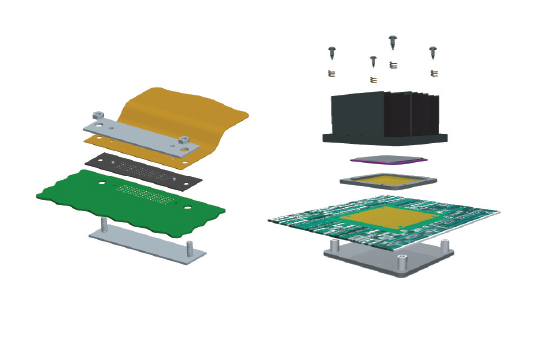

The connectors are positioned and mounted between boards and components using generally available alignment and compression hardware. Hardware can be press fit into PCB or utilized with a bolster plate for maintaining even compression across a large socket. Designers recommend PCB layout for gold plated pads and alignment holes locations.

View the complete technical documentation and product specifications for CIN::APSE® Solderless Compression Connector Technology.

View Brochure